Micro impurity

● Using higher quality scrap to remove impurities in molten steel

Smelting with Electric Arc furnace and Refining furnace to reduce the S,P content under 0.01%

Cast steel shot

Jun 20,2025

Cast steel shot

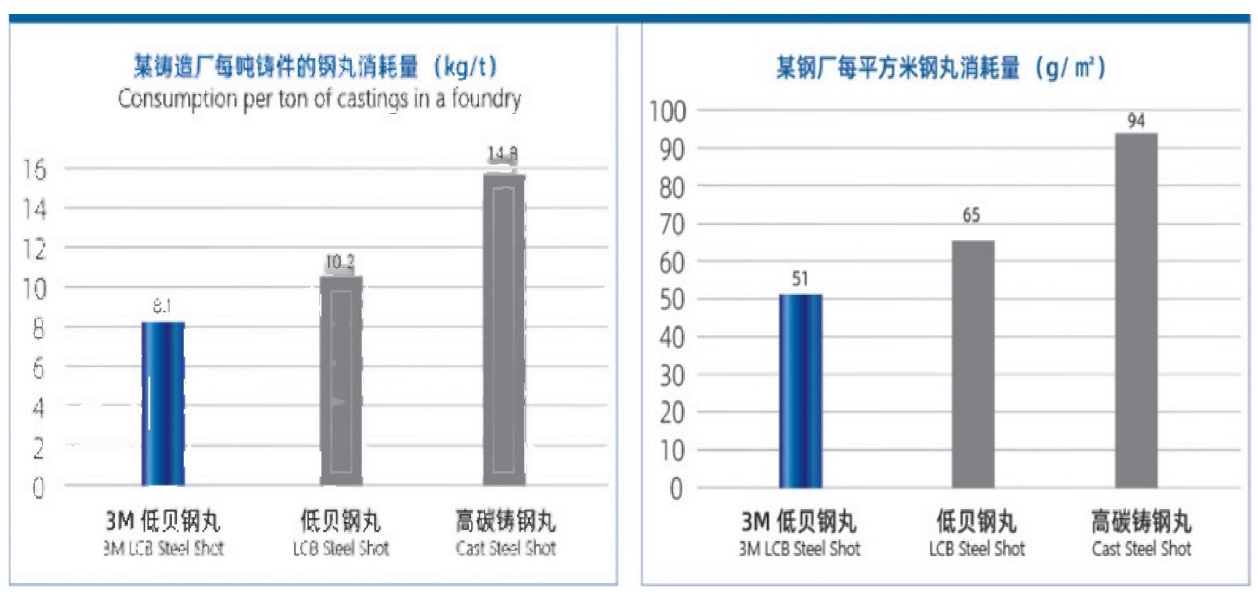

The product can be applied to all shot blasting and shot peening fields.Approved by industrial users,it has the characteristics of long life and high efficiency,and can significantly reduce the cost of shot blasting/peening which is the ideal choice of shot blasting media to reduce cost and increase efficiency.

The operational efficiency of cast steel shot provides significant economic advantages. Its high recyclability—often exceeding 2,000 cycles in properly maintained blast equipment—reduces material costs and waste generation. The spherical shape ensures smooth flow through blast machinery, preventing clogging and maintaining consistent velocity for uniform surface treatment. Available in sizes from S70 to S780, it can be selected to match specific surface finish requirements, from delicate precision components to heavy steel fabrication. Environmental considerations are addressed through its non-toxic composition and the ability to collect and reuse the media multiple times, aligning with sustainable industrial practices.

Quality assurance is paramount in cast steel shot production, with leading manufacturers adhering to international standards such as SAE J827, MIL-S-851, and EN 14251. Advanced testing methods including sieve analysis, hardness verification, and microstructure examination guarantee batch-to-batch consistency. When used in wheel blast or air blast systems, operators benefit from its predictable breakdown pattern, which maintains effective particle size throughout extended use. Industries ranging from aerospace and defense to general metalworking rely on cast steel shot for its unparalleled combination of cutting efficiency, surface enhancement capabilities, and long-term cost performance, establishing it as the gold standard for industrial abrasive blasting applications.

Related Posts

The Versatility of Zinc Cut Wire Shot in Abrasive Applications

Why Aluminum Cut Wire Shot is Your Best Choice for Surface Finishing