Micro impurity

● Using higher quality scrap to remove impurities in molten steel

Smelting with Electric Arc furnace and Refining furnace to reduce the S,P content under 0.01%

Contact Us

Tel:

E-mail:

Address:

PFN Germany GmbH Hammer Landstrasse 117 41460 Neuss Germany

Cast steel shot

- Product description

- Technique index

- Application areas

- Sizes

- Packaging

-

Cast steel shot

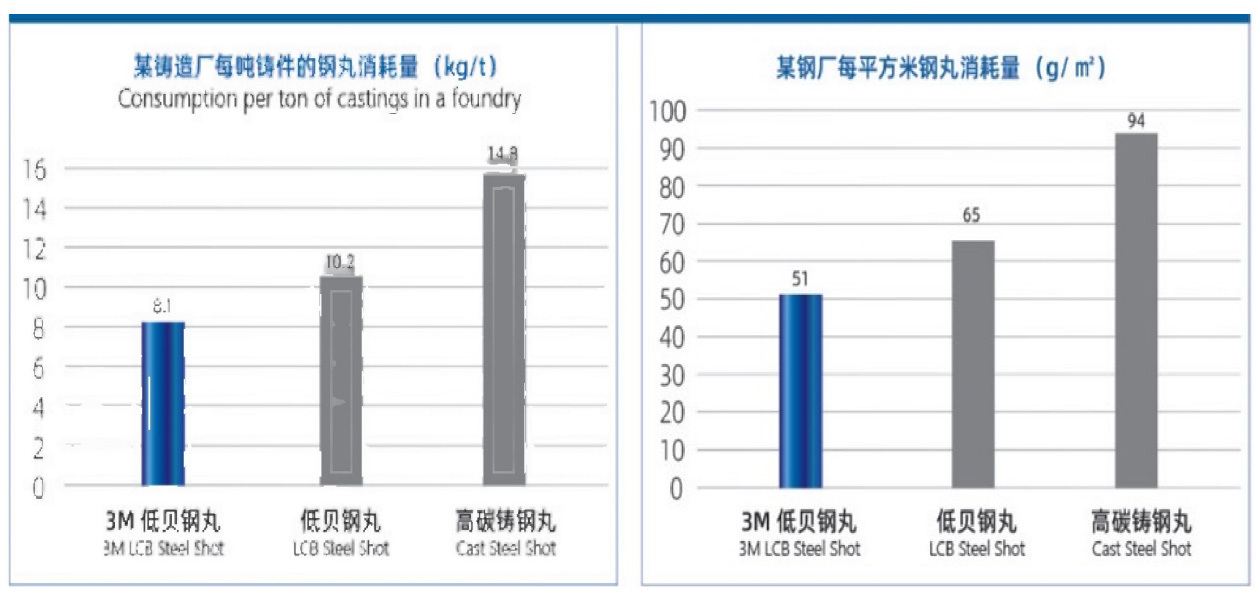

The product can be applied to all shot blasting and shot peening fields.Approved by industrial users,it has the characteristics of long life and high efficiency,and can significantly reduce the cost of shot blasting/peening which is the ideal choice of shot blasting media to reduce cost and increase efficiency.

Cast steel shot is a high-performance abrasive media widely used in surface preparation, cleaning, and strengthening applications across various industries. Manufactured through a precise melting and quenching process, this spherical abrasive offers exceptional durability, consistent hardness, and superior impact resistance, making it ideal for demanding shot blasting operations. Its uniform particle size distribution and controlled metallurgical properties ensure efficient material removal, optimal surface profiling, and reliable peening effects while minimizing dust generation and media consumption.

Produced from high-carbon steel alloys, cast steel shot undergoes rigorous quality control to achieve hardness levels typically ranging from 40 to 65 HRC, allowing customization for different surface treatment requirements. The manufacturing process involves melting high-quality steel in electric arc furnaces, atomizing the molten metal into spherical droplets, and carefully heat-treating the particles to obtain the desired microstructure. This results in a product with excellent fatigue resistance and the ability to withstand repeated impacts without premature fracturing, significantly extending its usable life compared to alternative abrasives.

In industrial applications, cast steel shot demonstrates remarkable versatility. It serves as the preferred media for cleaning and descaling metal surfaces in foundries, forging plants, and automotive component manufacturing. Its consistent performance removes rust, mill scale, and old coatings from steel structures, ships, and bridges while creating an ideal anchor pattern for subsequent painting or coating. When used in shot peening, the controlled impact of cast steel shot induces beneficial compressive stresses in metal parts, enhancing fatigue life and resistance to stress corrosion cracking in critical components such as aircraft landing gear, turbine blades, and suspension springs.

-

Technique index

Comparison of the main index

Categor

3M LCB Steel Shot

CB Steel Shot

Cast Steel Shot

Hardness

HRC

40-50

40-50

40-50

Density

g/cm³

7.6

7.4

7.2

Chemica

(%)C

0.08-0.15

0.1-0.2

0.85-1.2

S

≤0.02

≤0.035

≤0.05

P

≤0.02

≤0.035

≤0.05

-

Packaging

Hot Tags:

Cast steel shot

PREVIOUS:

NEXT:

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!