Contact Us

Tel:

E-mail:

Address:

PFN Germany GmbH Hammer Landstrasse 117 41460 Neuss Germany

High durability cut wire shot

- Product description

- Technique index

- Application areas

- Sizes

- Packaging

-

High durability cut wire shot

Based on the production process of traditiond steel cutwire,we have made substantial improvements on material and technological process:

- Utilizing high quality alloy steel wire as the substrate,the mechanical properties are more stable and higher.

- Improving the drawings und heat treatment process which make the internal organization more dense.

- Improving the traditional conditioning process completely relying on impacting to reduce the damage during blasting,enhancing the service life.

-

Technique index

Chemical

CompostionC

0.45%-0.85%

Si

0.15%-0.35%

Mn

0.30%-1.30%

S

<0.050%

P

<0.040%

Fe

the remaining

alloy elements

appropriate amount

Hardness

HV300-350, HV420-520, HV500-555, HV610-670, HV670-740, HV800

Density

≥7.4g/cm³

Bulk density

ca. 4,4 – 4,8 g/cm³

Microstructure

tempered martensite

*depending on grain size

-

Application areas

Surface deformations

Surface hardening (shot peening)

Application features

- Maintaining higher fatigue life under high strength,reduce the consumption costs.

- Good grain roundness,uniform size,no broken during using,gaining higher shot peening quality.

- Most cost-effective when used for shot peening of medchnical parts with hardness range of HRC40-56

-

Sizes

Spherical

Diameter(mm)

0.3,0.4,0.5,0.6,0.7,0.8,0.9,1.0,1.2,1.4,1.6

Other grain sizes can be produced if required.

Blasting System

Pressure blast machines

Wheel blast machines

Specification

EN ISO 11124-5, DIN 8201-4, SAE J441, AMS 2431/3, AMS 2431/8, VDFI 8001

-

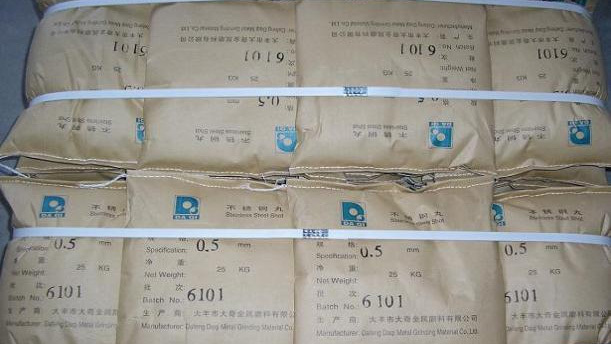

Packaging

25 kg bags on 1t pallets or 1 ton loose in a big bag

Hot Tags:

High durability cut wire shot

PREVIOUS:

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!